Vattenfall installs the next wind farm on giant inverted buckets instead of piling foundations into the seabed.

Normally, offshore wind power foundations are driven into the seabed by piling, a method that can cause a lot of noise and disturbance for sea mammals and fish and nearby coastal communities.

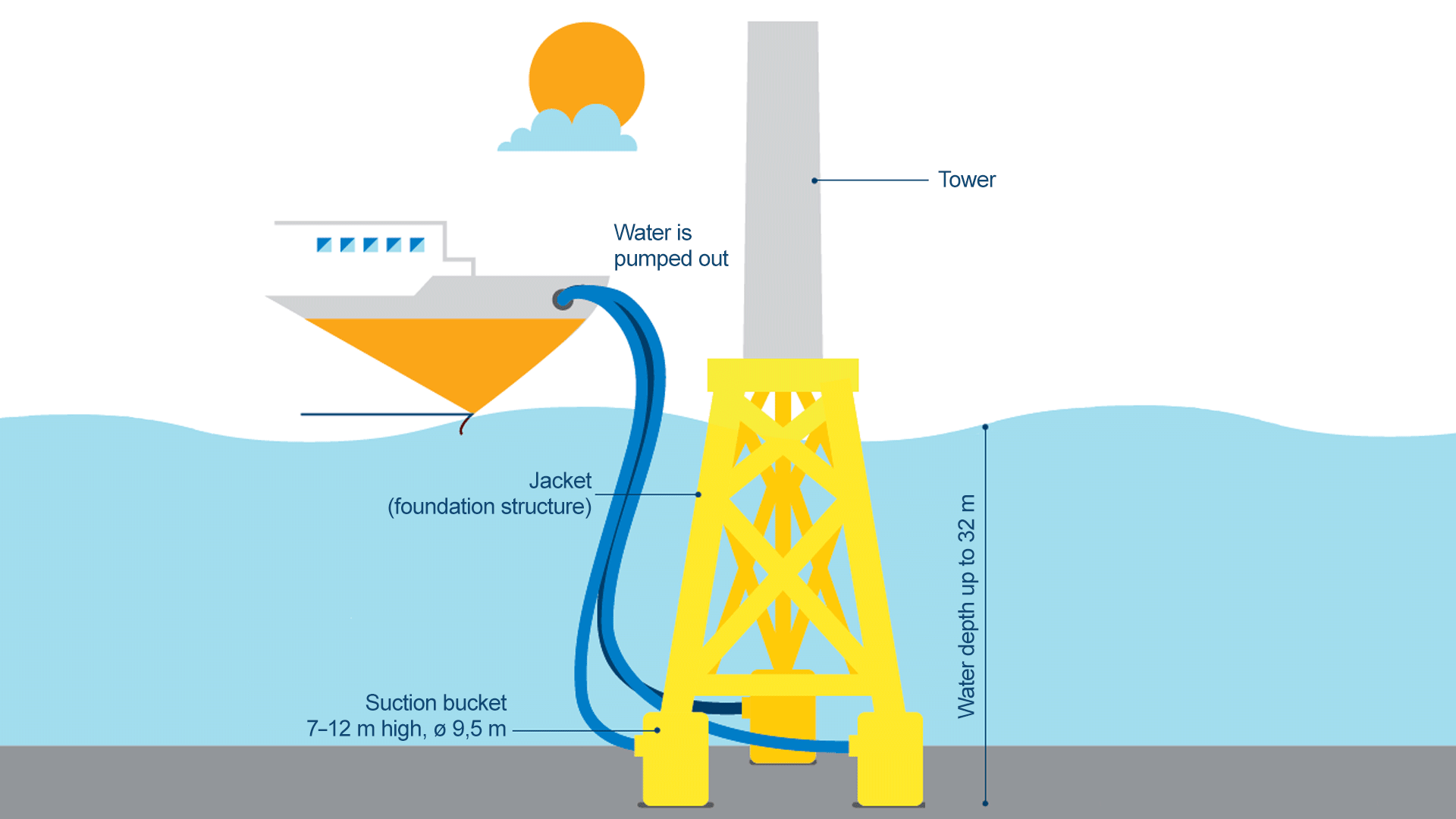

Vattenfall has now adopted the suction-bucket technology that is virtually noiseless. Instead of monopiles, these giant upside-down buckets paired with jacket substructures will anchor the wind turbines to the seabed.

Waterpumps instead of pile drivers

The suction bucket technology is well known in the oil and gas industry but this is the first time it will be used at a commercial scale in the offshore wind industry.

During installation, water is pumped out of the buckets, creating a pressure difference that forces the buckets into the seabed. In principle, piledrivers are replaced by water pumps.

When water is pumped out of the suction buckets, they sink in to the sea bed sediment. For decommissioning, water is pumped back in to retrieve the entire structure.

Construction in Aberdeen Bay

By the end of this year, offshore construction work will start at Vattenfall’s innovative European Offshore Wind Deployment Centre (EOWDC) located in Aberdeen Bay.

“The seabed conditions in Aberdeen Bay are ideal for this foundation concept and as Scotland is known for its whales and dolphins, we will minimize the sound impact on these animals. Also, reducing the noise from pile driving is expensive, an investment that is not needed with this technology. We also reduce disturbance for people living in nearby villages at the coast. Last but not least, when the wind farm’s life has come to an end, the decommissioning process is just a reversal of the installation process – you simply pump the water back in and retrieve the entire structure,” says Adam Ezzamel, project leader for the European Offshore Wind Deployment Centre.

The foundations with their giant buckets, 10.5 metres in diameter, are currently being assembled in Newcastle, UK.

Vattenfall’s European Offshore Wind Deployment Centre in Aberdeen bay will be the first commercial use of the suction bucket technology in a wind farm.

Increases the possibilities for offshore wind power

To make sure the suction bucket installation is successful, there has been a lot of investigation of the sea bed conditions along with offshore prototypes and full-scale trials. This is especially important as the foundations are to carry the world’s most powerful, 8.4 megawatt, wind turbine.

“We believe that suction buckets may give us better options as the industry moves towards deeper water and larger turbines. The technology is especially suited where the soil conditions are not suitable for monopiles and it could open up new areas for offshore wind,” Ezzamel says.

High voltage saves copper

In addition to the suction bucket foundations and the giant turbines, a third novelty in the Aberdeen project is high voltage 66 kilovolt inter-array and export cabling, rather than the traditional 33 kilovolt seen at other wind farms. This will reduce power losses and installation costs and also result in significant copper savings.

“I firmly believe that in the future all wind farms will use a 66 kV infrastructure because the benefits are so significant. And the bigger the wind farm, the more you save,” says Ezzamel.

The European Offshore Wind Deployment Centre (EOWDC), will have a total capacity of 92.4 MW once it is completed in September 2018. The centre is a test and demonstration facility to develop new technologies for offshore wind power. It also hosts a 3 million euro scientific research programme to study the environmental and socio-economic impacts of offshore wind.

Suction bucket jacket foundations

- Height: 60–78 meters

- Weight: 1800 tonnes (heaviest foundation)

- Suction bucket diameter: 9.5–10.5 meters

- Suction bucket length: 9–13 meters

Video of suction bucket technology

Video player requires marketing cookies.

To view this content please click here to allow marketing cookies.