Electrification, innovation and hydrogen gas reduce industry dependence on fossil fuels

Industry needs help in order to reduce its carbon dioxide emissions. Vattenfall is making it happen through cooperation and partnerships with industry.

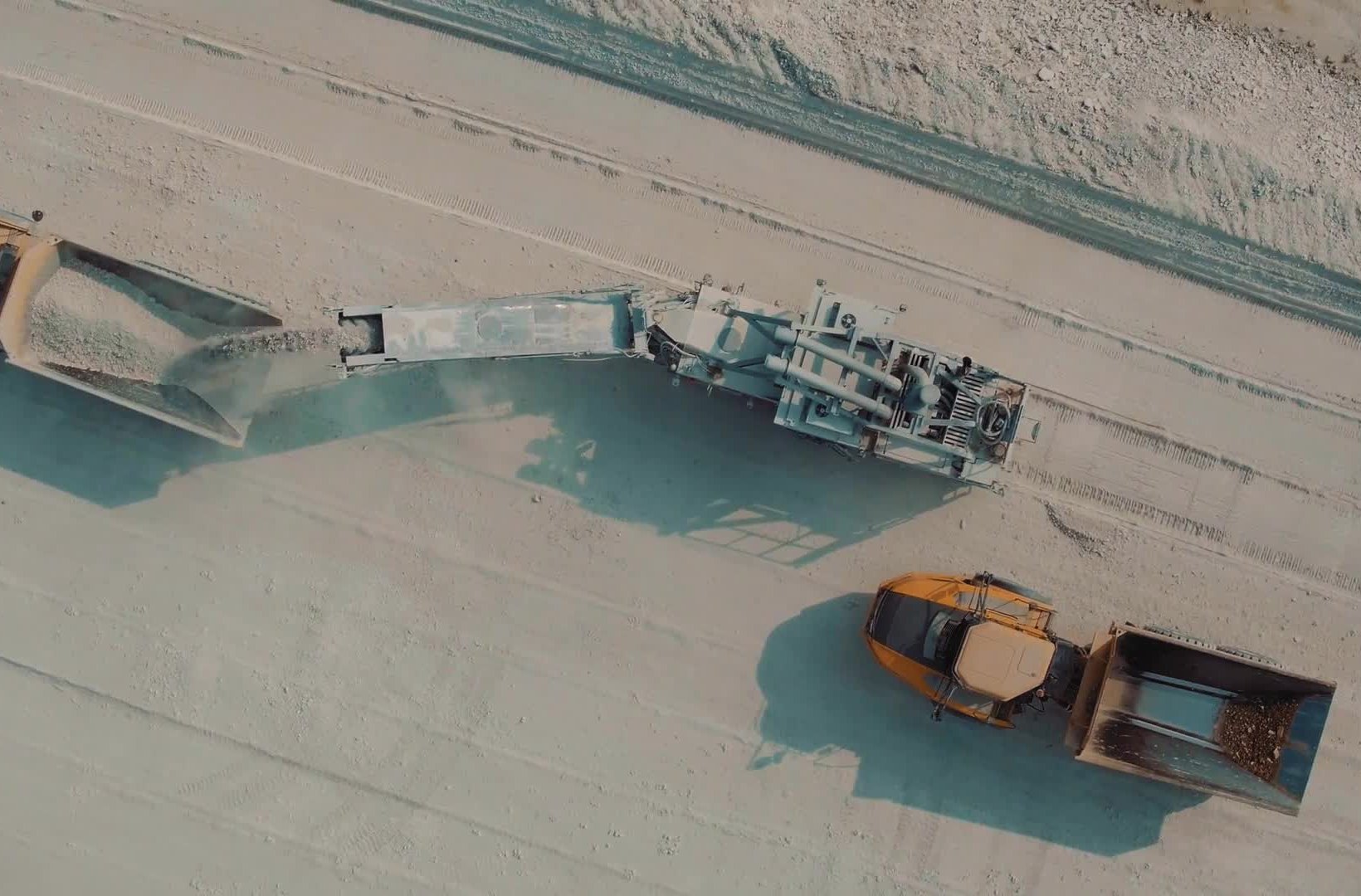

This year will see the inauguration of HYBRIT's pilot plant in Luleå, Sweden. In this plant, a tonne of fossil-free steel will be produced from raw iron ore every hour. By means of hydrogen that Vattenfall contributes to the process, the emissions take the form of water vapour instead of the 1.6 tonnes of carbon dioxide otherwise generated by every tonne of steel.

Video player requires marketing cookies.

To view this content please click here to allow marketing cookies.

Andreas Regnell, Head of Strategic Development, and Mikael Nordlander, Head of Industry Decarbonisation at Vattenfall R&D, are helped by Sofia Mankert, Head of Business and Corporate Communication, to describe how, through innovation and partnership, Vattenfall is helping industry to reduce its carbon footprint and, in many cases, its dependence on fossil fuels.

HYBRIT is a collaboration with steel manufacturer SSAB and mining company LKAB, but only one of a series of important partnerships that Vattenfall has with heavy industry. Other projects under way in Sweden, apart from HYBRIT, include the CemZero project with Cementa, which aims to reduce emissions from cement manufacturing, and fuel manufacturer Preem with the aim to increase production of biofuels.

In Sweden, electrification of these companies alone would enable the country's carbon dioxide emissions to be cut by 30 per cent or more.

At a global level the potential is enormous, as the steel, cement and fuel industries are the industries with the biggest carbon dioxide emissions. And a transformation is needed: for example, demand for cement has risen from one billion to four billion tonnes per year since 1990, and in the last ten years the demand for steel has risen by no less than 40 per cent.

Climate: the big issue

The big issue is how we can succeed in continuing to build our modern societies while at the same time keeping carbon dioxide emissions, and therefore climate change, at bay. Part of the solution is to use electricity or electricity processed into fossil-free hydrogen to replace fossil fuels and raw materials in the industries' processes.

"We believe in using electricity to reduce industry's climate impact," says Andreas Regnell, Head of Strategic Development. We call it Electric ReGeneration, and it's about using electrical power not just as a source of power but also as a source of innovation. In partnership with industry, we want to revolutionise and improve traditional processes and contribute to a transformation."

Hydrogen a key part of various processes

Hydrogen, which is produced from fossil-free electricity and water, is a key part of the process for fossil-free steel, and can also reduce carbon dioxide emissions from other industries, both as an energy carrier and as a raw material. One of the most spectacular examples is that hydrogen gas, together with captured carbon dioxide, can be used to manufacture methanol, which is in turn is a raw material for plastic, carbon fibre and chemical products. In agriculture, hydrogen gas can be used in the manufacture of fossil-free fertilisers.

"With the aid of fossil-free manufactured hydrogen gas, and by replacing fossil fuels with fossil-free electricity, we can contribute to a radical reduction in emissions from heavy industry," says Mikael Nordlander, Head of Industry Decarbonisation at Vattenfall R&D.

Read more about how electrification is being used to reduce industry's carbon dioxide emissions