As the debate about carbon capture and storage (CCS) rages on elsewhere, carbon dioxide has been successfully stored deep below the North Sea outside the coast of Norway since 1996, in the world’s first commercial CCS project.

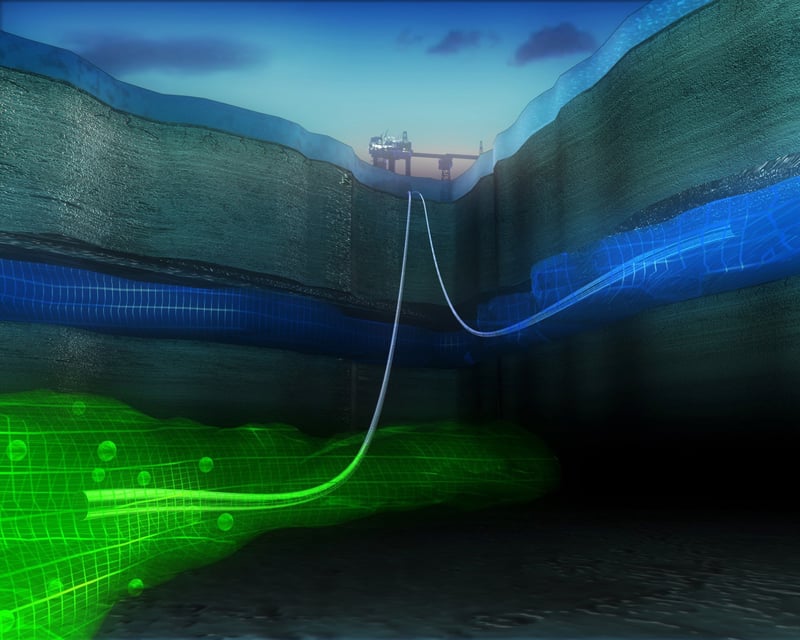

3D visualisation of CCS at Sleipner, copyright Equinor

For almost 30 years, Statoil – now Equinor – and partners have been separating CO2 from gas extracted in the Sleipner field and injecting it into the Utsira Sand formation more than 800 meters below the seabed. After being injected in liquid form into the highly porous sandstone, the carbon dioxide is trapped under a shale caprock which acts as roof, sealing and preventing the CO2 from ascending. Because of the depth, pressure and temperature, it stays liquid.

The main reason behind the decision to start the project nearly three decades ago was the Norwegian CO2 taxes that had been introduced a few years earlier and the high CO2 content of the gas at around 9 per cent, which exceeds market requirements. The taxes made the CCS operation more profitable than to just separate the carbon dioxide and release it into the air. Until now, more than 19 million tonnes of CO2 have been stored.

Technology from oil and gas sector

The technologies used for doing all this are neither new nor particularly high-tech, says Christian Bernstone. He works as an engineer at Vattenfall, currently in the company’s project for creating negative emissions through bio energy carbon capture and storage at the biomass fuelled combined heat and power plant in Jordbro outside Stockholm, where he manages the carbon dioxide transport and storage part. He has previously co-authored an EU funded best practice manual for CO2 storage based on the Sleipner project which was published by the British Geological Survey.

Vattenfall engineer Christian Bernstone at the Norvik harbour in Nynäshamn outside Stockholm, one of the harbours considered for shipping liquid carbon dioxide from Vattenfall’s Jordbro combined heat and power plant when a project for negative emissions through bio energy carbon capture and storage is running.

“It is conventional technology from the oil and gas industry that is used. These are techniques that have been around for a long time, since oil and gas exploration began basically. This is just the reverse, you are adding something instead of extracting something,” says Bernstone.

Data gathering, modelling and measuring techniques have developed since 1996 though, so it has become easier for engineers to foresee how the CO2 will act in different geological formations once injected. Aside from that, there have mainly been advancements in technologies for carbon dioxide separation, resulting in more energy-efficient processes.

New technology also makes it possible for ships that carry liquid CO2 to pump the carbon dioxide into floating injection platforms. From there the carbon dioxide is pumped directly into the storage facility – instead of laying a pipeline from land – since most storage will not be done near the source as is the case with Sleipner.

Also when looking for new places to store carbon, the CCS industry can – somewhat ironically maybe – lean on the oil and gas industry. Because it is not only the tools that are the same. It is also the same kind of geological formations in which oil and gas fields can form that are suitable for CO2 storage. And there are a lot of data from previous oil and gas exploration that can be used when looking for places to store carbon dioxide.

Legislation now in place to guarantee safe storage

Another thing that has developed is legislation. In 1996, there was no CCS-specific legislation, but since then lawmakers in Europe, the United States and other parts of the world have drawn up strict rules.

In the EU, the CCS directive is in place since 2009, and while Norway is not an EU member, the directive is implemented in Norwegian law through the Agreement on the European Economic Area (EEA).

The CCS directive aims to eliminate any significant risk of leakage or damage to human health or the environment. One of the criteria for getting a permission to start a CCS facility is to show that the storage is carefully monitored and safe over time to prevent any leaks.

That means Vattenfall and other companies looking to buy storage can feel safe that the CO2 will be handled securely, says Bernstone.

“You can be confident that the regulations in place have stringent requirements that must be met to obtain a storage license,” he says.

It was fortunate that Norwegian taxes incentivised the start of commercial CO2 storage already nearly 30 years ago, says Bernstone. That way, we have gained massive amounts of information and learned plenty as the fight against climate change has become more urgent than ever before. And that CCS can become an important tool, especially to decarbonise hard-to-abate sectors such as cement production and aviation.

“Above all, we have learned that carbon storage really works as it was intended to work,” says Bernstone.