“Yes, there is no tomorrow!”

Fossil fuels have contributed to an extraordinary level of economic transformation during hundreds of years. Now, we know that the environmental cost has been enormous, and the essential decarbonisation might seem to present overwhelming challenges.

Finding the solutions will absolutely not be easy – often demanding and difficult – but numerous examples show that it's indeed possible!

We use fossil fuels in every aspect of our daily lives, whether directly or indirectly, deliberately or unknowingly, for everything from cooking to heating houses, driving cars, generating electricity, and powering industry. Having used fossil fuels for more than 300 years has contributed to living standard increases and poverty alleviation worldwide. But the environmental cost of this progress has been enormous, and decarbonisation of several industries is now extremely crucial than ever before. It isn’t without challenges, but there are also prospects for innovation, developing new industries, and building new economies.

The challenges

Clay bricks are traditionally used to construct homes in India. Despite mostly being an unorganised business, India is the second-largest brick manufacturer in the world. The demand for clay bricks from the housing and infrastructure sectors is fueling the unregulated manufacturing of bricks. Most kilns, the ovens for burning the bricks, pollute the environment and significantly contribute to greenhouse gases and black carbon emissions. Also, brick kilns require vast quantities of clay, and mining of the clay causes irreversible damage to land and water resources. Despite the large-scale adoption of various brick technologies, the consumption of resources and energy required to make bricks hasn’t come down.

Sugar is a highly processed food ingredient. Growing sugarcane and then processing it to make refined sugar is a very energy-intensive process. About 550 million tons of greenhouse gas emissions will be added to the atmosphere every year due to sugar production. Drying and burning bagasse, a fibrous material left-over from crushing sugarcane, in the production of sugar further harms the environment. When there is not enough dried bagasse to burn, coal and gas are used to boil sugarcane juice to make sugar. Several stages in producing sugar further complicate efforts to reduce energy usage, thus remaining a big challenge for decarbonising the sugar industry.

The energy requirement for cooking has been rapidly changing. Liquefied petroleum gas, LPG, has helped millions of urban and rural households in India quit using the traditional biomass for cooking. With numerous cuisines, cooking methods, cooking vessels, and food ingredients, a household in India uses about 110 kg of LPG a year. The use of LPG has resulted in a significant surge in carbon-intensive fuel emissions that shows no sign of declining. Therefore, to reduce the demand for LPG imports and ensure energy security, India is promoting electricity-based cooking equipment. It will further increase the requirement for electricity production from fossil fuels.

Long-haul flights using renewable energy are difficult to accomplish because present renewable energy choices can’t match the superior energy output of jet fuel in the aviation industry. In a similar comparison, very high energy output is mandatory for several manufacturing processes, such as those that produce cement, steel, and glass. It is difficult to achieve the energy output range of 1200–1800°C, which is essential for these processes, without the use of fossil fuels. The energy density of fossil fuels is economical, efficient, and superior to that of existing renewable energy choices. Most non-fossil fuels are quite expensive, and unavailable in large quantities.

The solutions

A few days ago, I visited a new house in my town, Tiruvannamalai in southeastern India, entirely built with eco-friendly bricks made from local materials. The bricks were made by mixing fine soil, fly ash, sand, lime powder, plaster of Paris, rice straw, wood sawdust, salt, and water. The bricks were sun-dried and baked using dried sugarcane bagasse and leaves. The bricks were cool to the touch! A team of architectural students has tested the temperature differences in and out of the house and found that the interior is noticeably warmer even in the winter months of November and December. The occupants of the house said that they haven’t used the air conditioner for months and run the fans at a lower speed, saving electricity.

At home, we made the shift to using palm sugar years ago and haven’t missed using refined sugar. Because it is produced with insignificant processing and no additional preservatives, palm sugar is a healthier choice than other sugars and sweeteners. It also contains a considerable amount of plant-based iron, vitamins, and minerals that are beneficial to active living. Palm sugar has a lower glycemic index, which reduces the probability of a blood sugar surge. In traditional Indian medicine, palm sugar is prescribed as a suitable substitute sugar for diabetics. I’m so happy to see that several supermarkets now sell palm sugar in sugar form, powder form, and honey-like form.

Though the use of cooking gas is common in India, the availability of gas cylinders in rural and remote villages is random. In such places, people use a compact biogas maker, which has a tank where anaerobic bacteria break down organic kitchen waste, producing about 75 % flammable methane and other gases. The gas is stored in an upper tank, which floats in water and moves up or down as per the volume of gas produced. If gas is overproduced, it is immediately let out due to buoyancy, ensuring safety. The biogas travels through a pipe connected to a biogas stove, similar to LPG stoves, and is primarily used for cooking. Waste to wealth is no longer a green joke!

It came as a surprise to me that the seeds of a humble-looking tree grown on the sides of roads here in India, to provide shade, could actually power long-haul flights! Bio-fuel made from the Karanja tree (Pongamia pinnata) could be successfully used as an alternate fuel instead of jet fuel, as its energy output properties are very identical. The biofuel made from Karanja oil is tested in jet engines, and its results were compared with jet fuel. From the test results, Karanja oil biofuel can be used in direct injection jet engines and can be a better alternative fuel for other jet engines as well. Efforts are being made to grow the Karanja tree as a rural crop with formal training and subsidies.

As an innovator, I believe that challenges fuel research, innovation, and economic growth. Both developed and developing countries have no choice but to transition to a fossil-fuel-free economy: yes, there is no tomorrow. It is absolutely not going to be easy, but difficult, not impossible. We should work together and share our experiences for a world in which our future generations can live without environmental and climate catastrophes. All our efforts, small and big, will eventually shape the future of our earth and the people who’ll inhabit it. It is our collective responsibility to keep our differences aside and work together for the long-term benefit of the only planet we actually call our home.

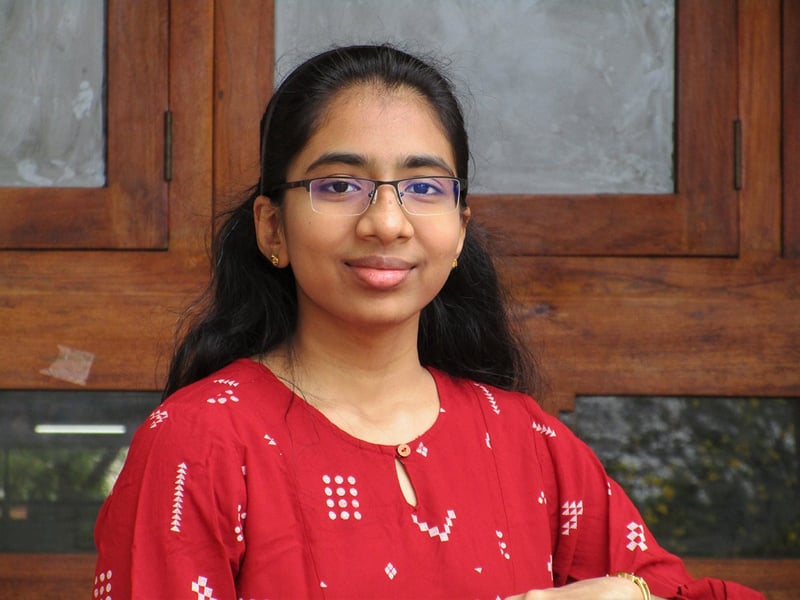

Vinisha Umashankar

Student at UWC Mahindra College, innovator, environmentalist, Yale Young Global Scholar 2024, National Youth Award winner 2024 and 2021, speaker at TEDx, the COP26 World Leaders’ Summit and much more.

Vinisha Umashankar on Linkedin